Seafood Processing Chlorine Dioxide

Price 1200 INR/ Liter

Seafood Processing Chlorine Dioxide Specification

- Density

- 1.64 Gram per cubic centimeter(g/cm3)

- HS Code

- 28289090

- Structural Formula

- O=Cl[O]

- Molecular Weight

- 67.45 g/mol GSM (gm/2)

- Taste

- Pungent, metallic

- Solubility

- Easily soluble in water

- Other Names

- Clo2, Chlorine oxide

- Shape

- Powder or liquid (depending on formulation)

- Purity

- 99%

- Form

- Powder/Liquid

- Poisonous

- No

- Boiling point

- 11°C

- Storage

- Store in a cool, dry place away from sunlight, in tightly sealed container

- Molecular Formula

- ClO2

- Classification

- Oxidizing agent

- Chemical Name

- Chlorine Dioxide

- Grade

- Industrial, Food Grade

- Type

- Disinfectant

- Usage

- Food industry sanitizer, disinfectant

- Main Material

- Chlorine dioxide

Seafood Processing Chlorine Dioxide Trade Information

- Minimum Order Quantity

- 1000 Liters

- Supply Ability

- 1 Liter Per Week

- Delivery Time

- 3 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Seafood Processing Chlorine Dioxide

Our name is identified as one of the dynamic manufacturers and suppliers of Seafood Processing Chlorine Dioxide. These chemicals are used as an excellent odor neutralizer in sea food processing industry for neutralizing foul smelling odors. Formulated from certified quality of compounds, all these chemicals are available in different grades. Numerous clients of the industry highly acknowledge these chemicals for their optimum pH value, accurate composition and longer shelf life. We offer this Seafood Processing Chlorine Dioxide to our clients at market leading price.

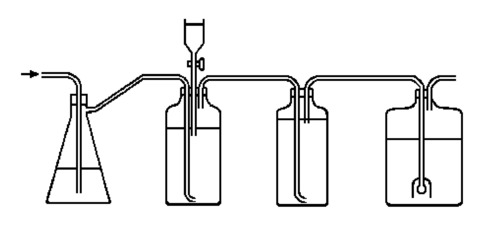

Comprehensive Disinfection for Seafood Processing

Chlorine Dioxide serves as an advanced disinfectant, effectively eliminating a wide range of pathogens in seafood processing. Its strong oxidation capability ensures thorough sanitation of surfaces, equipment, and water, keeping operations hygienic and compliant with safety standards. Flexible in use, it can be applied in various forms to meet specific process needs, improving product quality and staff safety.

Safe and Efficient Application

The products high solubility allows rapid preparation for immediate use in seafood processing. Operators benefit from its stability when stored as instructed, while the HDPE packaging safeguards handlers from accidental exposure. Ensuring correct usage protocols and adherence to storage guidelines maximizes effectiveness and minimizes risk during disinfection routines.

Advantages of Chlorine Dioxide in Seafood Industry

Chlorine Dioxide offers several advantages over traditional sanitizers. Its robust antimicrobial action, high purity, and adaptability in powder or liquid forms make it a versatile option for seafood processors. Using food-grade ClO2 ensures compliance with food safety regulations and supports the production of high-quality, contaminant-free products.

FAQs of Seafood Processing Chlorine Dioxide:

Q: How should Seafood Processing Chlorine Dioxide be stored to maintain its stability?

A: Store Chlorine Dioxide in a cool, dry area away from sunlight, making sure that the container is tightly sealed. Proper storage conditions are essential to maintain its stability and effectiveness during use.Q: What is the main process for using Chlorine Dioxide in seafood disinfection?

A: To disinfect seafood or processing surfaces, dissolve the specified amount of Chlorine Dioxide in water; the products high solubility enables rapid preparation. Apply the solution following recommended concentrations and safety procedures.Q: When is the best time to use Chlorine Dioxide in seafood processing operations?

A: Chlorine Dioxide should be used before, during, and after seafood processing to ensure surfaces, water, and products are sanitized and meet hygiene standards, minimizing risks of microbial contamination.Q: Where is this sanitizer commonly applied in the seafood processing industry?

A: Common applications include direct seafood disinfection, water treatment cycles, and sanitation of work surfaces, processing equipment, and storage areas within seafood processing facilities.Q: What precautions should be taken when handling Chlorine Dioxide?

A: Always handle Chlorine Dioxide with care, as it is poisonous and classified as a 5.1 Oxidising Agent. Wear protective equipment, follow safety guidelines, and ensure proper ventilation during use to mitigate hazards.Q: How does Chlorine Dioxide benefit seafood processors compared to other disinfectants?

A: With 99% purity and effective microbial control even at low concentrations, Chlorine Dioxide offers reliable sanitation. Its stability, versatility in forms, and compliance with food-grade requirements help seafood processors uphold safety and quality standards.

More Products in Liquid Chlorine Dioxide Category

Liquid Stabilized Chlorine Dioxide

Price 240 INR / Liter

Minimum Order Quantity : 1000 Liters

Usage : Industrial and Domestic Disinfectant

Solubility : Completely soluble in water

Purity : 10% 20% (liquid stabilized form)

Grade : Industrial Grade

Industrial Liquid Chlorine Dioxide

Price 1200 INR / Liter

Minimum Order Quantity : 10 Liters

Usage : Industrial Water Treatment, Bleaching, Disinfection

Solubility : Soluble in Water

Purity : 99%

Grade : Industrial Grade

Chlorine Dioxide For Brewing Process Industry

Price 2000 INR / Liter

Minimum Order Quantity : 1000 Liters

Usage : Sterilizing agent in brewing

Solubility : Soluble in water

Purity : 99%

Grade : Industrial Grade

Dairy Farm Chlorine Dioxide Chemical

Price 12000.00 INR / Liter

Minimum Order Quantity : 10 Liters

Usage : Commercial

Solubility : Water

Purity : High

Grade : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS